Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal St.

Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

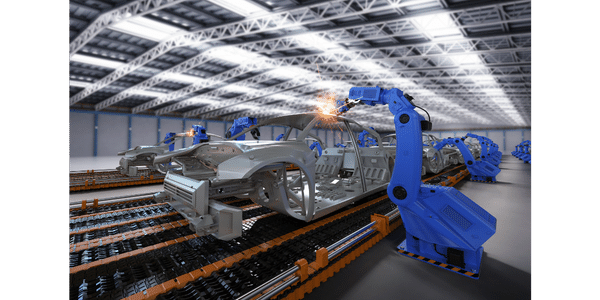

The future of manufacturing is being shaped by integrating artificial intelligence systems. AI in manufacturing is revolutionizing the way factories operate, improving productivity, efficiency, and overall performance. This article explores the role of AI and manufacturing plus its profound implications for the industry’s future.

AI is not here to replace human workers. Instead, it enables collaboration between robots and personnel to achieve tasks more efficiently. With the advancement of technologies, manufacturing processes are becoming faster, more precise, and equipped with enhanced quality control. This article explores the applications and importance of AI in manufacturing, shedding light on its transformative role in shaping the future of factories.

Far from the sci-fi vision of completely autonomous factories, AI in manufacturing is all about smart applications for specific processes. These systems act independently, responding intelligently to whatever life throws at them. Whether it’s a worn-out tool, a system outage, or something as unpredictable as a fire or natural disaster, artificial intelligence keeps things running smoothly.

By integrating AI into their workflows, manufacturing companies can experience:

The growth of AI in the manufacturing industry is indeed quite astounding!

If you’re in the manufacturing industry and haven’t started exploring this new technology yet, you should get on!

Applications in manufacturing are wide-ranging, but two areas, in particular, stand out. The first is process automation. Machine Learning (ML) systems can reduce costly manual errors, enhancing productivity and slashing workforce costs. The era of automation AI is here, transforming manufacturing as we know it.

The second significant application is predictive maintenance. Systems can use data from a multitude of sensors to spot anomalies and equipment inefficiencies, helping to avoid unexpected downtime and reduce the need for part replacements. We’re talking about potential global cost savings in the range of $500-$700 billion.

Manufacturers have already seen how it has proved to be influential on their industry as they produce the most data, but they also discard most of it.

Artificial intelligence brings;

Manufacturers have already seen how intelligence is influential in their industry as they produce more and more data. Some major benefits for factories include:

This leaves human workers free to focus on more strategic tasks. As a result, manufacturers can achieve higher output levels, reduce operational costs, and improve overall competitiveness. You can read more about the amazing benefits of AI in one of our previous blogs.

The latest tech is not meant to replace humans. Instead, it empowers creative individuals to achieve more. Artificial intelligence facilitates the collaboration between humans and robots in the manufacturing industry. While industrial robots may require supervision, they are becoming smarter through innovation, paving the way for improved collaboration between humans and machines.

Following are 8 big ways artificial intelligence is reshaping factories.

Systems and robots can execute repetitive tasks with precision and speed, enhancing efficiency and increasing productivity. These intelligent machines can handle monotonous and labor-intensive jobs, freeing up human workers to focus on more strategic and creative tasks. As a result, manufacturers can achieve higher output levels, reduce operational costs, and improve overall competitiveness.

Prior to production, AI-based product development can create simulations to test the exact production features and circumstances. Not only that, but it can also create environmental simulations to design the product in any way desired or adapted to the environment and test it the same way.

For instance, fluid dynamics simulations take a long time to run, yet it’s crucial to comprehend the aerodynamics of an airplane component. Simulations speed up the runtime, allowing you to acquire results more quickly and go back to developing a smarter system.

Manufacturers reap tons of advantages:

Additive manufacturing, also known as 3D printing, is becoming increasingly important in the manufacturing industry. This modality has led to the integration of new types of sensors that monitor various conditions affecting materials and fabrication technology. The combination of AI and sensors enables real-time monitoring of the additive manufacturing process and the detection of anomalies or deviations that may impact product quality. By integrating machine learning and sensors, manufacturers can ensure optimal performance and reduce defects in additive manufacturing.

Maintaining product quality is crucial in manufacturing. Systems equipped with computer vision and machine learning capabilities can analyze vast amounts of data in real-time to identify defects, anomalies, and variations in production processes. This means that manufacturers can rectify problems swiftly, reduce waste, and deliver high-quality products to customers consistently. This highlights the incredible capability of AI and big data working in tandem.

The efficient management of the supply chain is critical for manufacturers to meet customer demands while minimizing costs. Technologies can analyze vast amounts of data related to inventory levels, demand patterns, and market trends. By providing real-time insights and predictive analytics, facilitates are smarter. They make better decisions in inventory management, demand forecasting, and logistics optimization. Also, it enables manufacturers to streamline their supply chain operations.

Artificial intelligence can be used as a response to demand volatility. Manufacturers can make use of Machine Learning algorithms to predict changes in supplies request as accurately as possible to improve demand forecasting. These algorithms can automatically recognize patterns and capture signals for demand fluctuation. As a result, production teams receive the supplies at the right time. In contrast, predictive analytics can help you order the right amount of stock so you won’t end up with too much or too little.

For example, think of a manufacturer of food products. The company requires more accurate and secure demand forecasts due to the short shelf-life of its fresh products and volatile demand. Implementing a machine learning system to make better demand forecasts is a considerable route. In addition, this system improves efficiency and inventory balance, allowing the company to achieve its target service levels for channel or store-level inventories.

One of the immediate applications of AI in manufacturing is predictive maintenance. By leveraging continuous streams of data from sensors, algorithms can detect patterns and apply analytics to predict potential problems before they occur. For example, acoustic sensors can listen for signs of wear in belts or gears, while other sensors monitor tool wear. This information is linked to analytic models that predict the remaining lifespan of tools, allowing for proactive maintenance scheduling.

Equipment failure and unplanned downtime can significantly impact manufacturing operations. AI-based predictive maintenance solutions leverage data analysis and machine learning algorithms to detect early signs of machinery faults and anticipate maintenance requirements. By identifying potential issues before they occur, manufacturers can schedule maintenance proactively, minimize disruptions, and ensure optimal equipment performance.

AI plays a vital role in optimizing factory planning and layout. By utilizing algorithms, manufacturers can design factory layouts that prioritize operator safety and enhance process flow efficiency. Simulations can help determine the best configurations for reconfigurable facilities that can accommodate changing processes and short-run projects. Through “what-if” analysis, manufacturers can evaluate different scenarios and make data-driven decisions for factory layout optimization.

AI is revolutionizing the manufacturing industry, bringing unprecedented efficiency, productivity, and decision-making advancements. It offers manufacturers a competitive edge in an increasingly globalized and demanding market, from optimizing production processes and ensuring quality control to streamlining supply chain operations. As machine learning continues to evolve and integrate with other emerging technologies, the potential for innovation and transformation in the manufacturing industry is immense.

AI plays a pivotal role in optimizing production processes by enabling intelligent automation, predictive maintenance, and quality control. It enhances operational efficiency, reduces downtime, and ensures consistent product quality.

AI benefits the manufacturing industry by enhancing operational efficiency, improving quality control, enabling predictive maintenance, optimizing supply chain management, and facilitating collaborative workflows between humans and robots.

AI benefits the manufacturing industry by enhancing operational efficiency, improving quality control, enabling predictive maintenance, optimizing supply chain management, and facilitating collaborative workflows between humans and robots.

AI improves supply chain management in manufacturing by leveraging data analysis and predictive analytics to optimize inventory management, demand forecasting, and logistics operations. It enhances visibility, reduces costs, and enables agile decision-making.

Yes, it can help reduce manufacturing costs through improved efficiency, optimized resource allocation, and predictive maintenance. Manufacturers can achieve cost savings and enhance their bottom line by streamlining processes and minimizing wastage.

Predictive maintenance is a proactive maintenance approach that uses data analysis and algorithms to predict potential machinery failures or maintenance requirements. By continuously monitoring machine performance and analyzing patterns, systems can alert maintenance teams to resolve issues before they cause downtime or disruptions.

No, AI is not meant to replace human workers in factories. Instead, it enables collaboration between humans and machines, enhancing productivity, safety, and efficiency in manufacturing operations.

While AI may automate specific tasks traditionally performed by humans, it also creates new job opportunities. The technology requires human oversight, maintenance, and strategic decision-making. Additionally, implementation can enhance human productivity and enable workers to focus on more skilled and strategic roles.

AI systems can analyze energy consumption data and identify areas where energy efficiency can be improved. By optimizing machine operation and resource allocation, It helps reduce energy waste, leading to cost savings and a more sustainable manufacturing process.

Yes, AI plays a significant role in product design and optimization. Through generative design algorithms and simulations, AI can explore multiple design iterations and optimize product performance based on specified requirements and constraints.

AI, in combination with sensors and data analysis, enables real-time monitoring of manufacturing processes, allowing for immediate detection of defects or deviations. Systems can identify patterns, compare them with quality standards, and alert operators when product quality falls below the desired threshold.

Implementing AI in manufacturing does come with challenges, such as data quality and security concerns, infrastructure requirements, and the need to upskill the workforce. However, these challenges can be addressed effectively with proper planning and strategic implementation.

As we look toward the future, it’s clear that AI will play a significant role in the evolution of manufacturing. With advancements in technology and the integration of other emerging technologies like the Internet of Things (IoT) and robotics, we can expect increased automation, improved decision-making capabilities, and further optimization of manufacturing processes. For more insights on how it’s impacting various sectors, be sure to check out our blog on AI in everyday life.